Solvent recovery uses a multi-stage distillation process to separate solvents into its components at lower-than-boiling point temperatures. Waste is removed and you’re left with clean solvent.

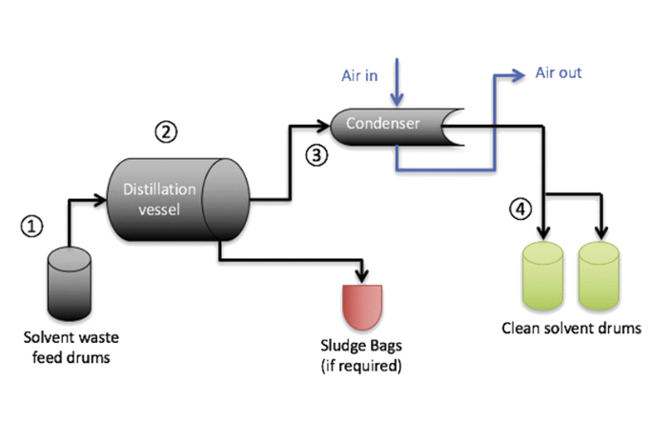

Solvent recovery process:

- The spent solvent is fed, either automatically or manually depending on the equipment, into the distillation vessel.

- The distillation vessel is fitted with a thermal oil jacket that is heated by one or more electric heaters which brings the spent solvent to its boiling point.

- Once the waste is separated, the recovered solvent vapors are channeled to an air cooled condenser, where it cools into its liquid form.

- The liquid is then directed to the clean solvent collection drums, where it can be reused.

Leave a Reply